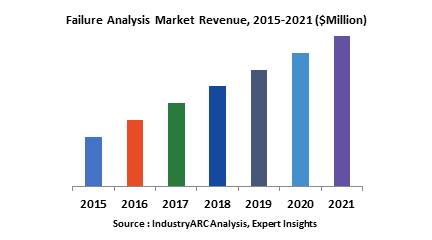

Failure Analysis refers to the analyzing the root cause for the failure in a material and correcting the root cause of the failure which can be done by using various analytical techniques, expert science interpretations. The failure analysis market is valued at $5.4 billion in 2017 growing at a CAGR of 7.7% during 2018-2023. The Industrial sector generated over $700 million in the year 2017. As the technology is evolving the tools for identifying and correction of failure has becoming easy and increase in usage of technology is driving the failure testing market

- The eddy current which is a nondestructive examination method used in failure analysis is being replaced by new techniques which are ultrasonic and radiographic techniques. By using this two new techniques the current flows within the adjacent joint layers as well as inside the conductive faster therefore reducing the current density around the crack

- The other new innovation particularly designed in detecting the sub surface cracks, is pulsed excitation of eddy currents. The penetration depth of eddy currents depends on excitation frequency this Pulsed Eddy Current (PEC) testing allows more volumetric inspection and fetches more information.

- Magnetic resonance imaging is another nondestructive examination method used in failure analysis focus on development of PET/MRI hybrid imaging system which combine the anatomical imaging and functional imaging data bringing the soft tissue characterization and imaging provided by MRI scans without ionizing radiations.

- The latest advancements in automotive failure analysis industry can be witnessed in vision based sensors and processors in-addition to artificial intelligence and high performance vehicles positioning and cloud connectivity. Manufacturers are developing performance analysis, vehicle dynamics studies, failure analysis, accident reconstruction, etc.

- Fourier transform infrared(FTIR) spectroscopy is one of the most widely applied techniques in failure detection which is well established in micro destructive analysis of small samples, the recent introduction of mapping and imaging equipment allow the collection of a large number if FTIR providing a distribution map of identified components.

- Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

- Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

- Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

- Analyze the sales and distribution channels across key geographies to improve top-line revenues.

- Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

- Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

- Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

- "We also publish more than 100 reports every month in “Automation and Instrumentation”, Go through the Domain if there are any other areas for which you would like to get a market research study."

Comments (0)

Post a Comment