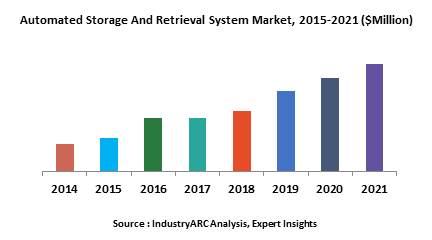

The global revenue generated by Automated Storage and Retrieval Systems in 2020 was $6.7billion, owing to growing need for automation in the supply chain industry, the market is estimated to grow at a CAGR of 6.1% throughout the forecast period. Unit Load and Mini Load Systems account for 54% of the market in 2020 and are projected to grow at a high rate of 7.9% through 2026. APAC is the market leader in 2020 accounting for 38% of the market. The region is expected to grow at the highest rate of 7.4% through 2026.

- Daifuku Co. Ltd, a Japanese based organization is one of the top players in this market. They have introduced a product called Clean Stocker which is for temporary storage in the semiconductor manufacturing industry. The shelf modules are expandable to match the required number of semiconductors to be stored. Consideration is also given to high transfer capacity, prevention of dust generation, and safety.

- Schafer Group has been successful in creating and updating their picking systems which are essential for efficient logistics chain and rapid order. Picking goods is one of the most cost effective and labor intensive processes for both warehouses and distribution centers. This enables you to process the orders quicker and more effectively. The types of picking systems include automated picking, Semi-automated picking and Manual picking. The system provides maximum productivity and an optimum material flow in the warehouse. It provides consistent quality, even during peak hours of activity.

- Honeywell Intelligrated Inc. have introduced Automated Storage and Retrieval Shuttle Systems which are used for higher volumes of products. The High Volume Buffer Shuttle (HVBS) system is an extensive, highly efficient case buffering system designed to keep shipping, receiving and other downstream processes running smoothly. The system uses multiple aisles in close proximity to enable high-density storage and serve operations with quick-turn inventories and high throughput requirements. The features include:-

b) The system handles both cases and totes.

c ) It offers flexibility to process both inbound and outbound loads in a bi-directional system.

- Murata Machinery Ltd., has introduced a three-dimensional structure Automated Storage and Retrieval Systems that provides the reliable solution for pallet storage. In addition to an integrated construction, it is also possible to comfortably install a single three-dimensional rack unit in the existing facility. By integrating other transport equipment, it is possible to build an optimal storage and transportation system for efficient material handling. It is mainly used in Pharmaceutical purposes for efficient storage of poultices, replacement fluid, and other products, thereby raising the efficiency of the center. Also the diverse packaging material (flexible container, cardboard, etc.) can be kept in the same area. It provides for anti-rust and protection from insects. It can be installed in a variety of facilities including refrigeration systems, clean rooms and near hazardous items.

- Swisslog Holding, a Switzerland based organization has the expertise in automated storage in small load applications. Small load storage covers a wide variety of boxes, totes and containers. In order to keep costs low, miniload warehouse automation systems need to be highly flexible and scalable. It provides right automation solution for small loads warehouse depending on several factors:-

- Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

- Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

- Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

- Analyze the sales and distribution channels across key geographies to improve top-line revenues.

- Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

- Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

- Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

"We also publish more than 100 reports every month in “Automation and Instrumentation”, Go through the Domain if there are any other areas for which you would like to get a market research study."

Comments (0)

Post a Comment