Engineering Plastics Market Overview:

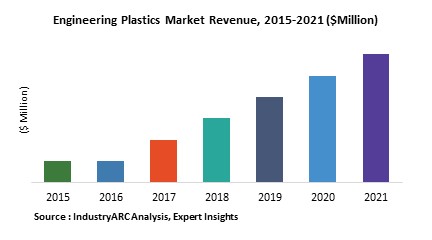

Engineering plastics are performance polymer materials that have better mechanical and thermal properties than the more widely used commodity plastics such as polystyrene, PVC, polypropylene and polyethylene. Owing to its peculiar traits such as stability, flame resilient, chemical resilient, exceptional machinability, dimension constancy, wear resistance, and minimal damaging friction, it has found tremendous scope of applications in various industries including automotive, aerospace, building and construction, mechanical, and medical. Capitalizing on the industrial trend of ‘lightweighting’ engineering plastics have been successfully replacing other engineering materials such as wood and metal and its global market size is valued at around $79716 million as of 2018. The analyst of this business intelligence report has tracked the engineering plastic market to be progressing at a global CAGR of around 6.6% during the forecast period of 2019-2025.

Engineering Plastics Market Outlook:

According to the International Organization of Motor Vehicle Manufacturers, 97.3 million vehicles were produced in 2017, a 2.36% increase compared to 2016[1]. The rapidly revolutionizing automotive sector with determined efforts to match up with the ‘lightweighting’ trend is implementing engineering plastics in several automotive parts. After metal parts, engineering plastics materials dominates the automotive composition materials. As a consequence of this trend, automotive sector is the major employer of engineering plastics market, growing with the application CAGR of around 7.5% going through 2025.

One of the prime reason for the sheer affluence of engineering plastic is its flexible physicality, predominantly missing from competitor engineering materials such as metal and wood. Due to this significant trait it has found tremendous scope of application in the modern era construction dealing with intricate infrastructures. Aesthetically appeasing glass frontages or arched and suspended structures and skyscrapers are filling the modern infrastructural setting, and engineering plastics with its flexibility benefits is augmenting the market demand through its application.

As per the Institute of Civil Engineers report directed by Oxford Economics, the volume of construction production will grow by 85% to $15.5 trillion globally by 2030, with two countries from APAC including China and India and the U.S leading the way and accounting for 57% of all global growth[2]. APAC with is augmenting automotive industry growth rate, India (5.83%), China (3.19%), and Japan (5.31%) as of 2017 and blooming construction sector is leading engineering plastic market with more than 42% of global demand falling under its own frontiers.

Engineering Plastics Market Growth Drivers and Trends:

- One of the major growth driver for the implementation of plastics in industrial operations is the ongoing ‘lightweighing’ trend. With amplified stress on reducing the load of the car, refining fuel efficacy and emissions, engineering plastics are swapping itself with numerous other materials.

- To comply with the similar trends, construction sector is equally preferring plastics for its operations. The construction production is adapting engineering plastic in its routines for a wide range of uses because of its versatility, strength-to-weight ratio, durability, corrosion resistance, and so on. Plastic can be artificial converted into pipes, cables, coverings, panels, films, sheets and so on and are being employed in this sector worldwide.

- Bio-based engineering plastics such as PLA and PHA and PET has found tremendous scope application in packaging, food service ware, bags, and agriculture applications. Owing to the growing demand for bio-based products, numerous vendors are offering bio-based engineering plastics in the market.

- Mitsubishi Chemical, a Japanese market giant, came up with its product DURABIO™, and found a major employer in automotive sector. It is employed as automotive housings interior and exterior décor.

Engineering Plastics Market Players Perspective:

Some of the major companies profiled in this business intelligence report operating in the global engineering plastic market are BASF SE, Solvay S.A., DowDuPont, SABIC, and DSM. BASF SE is offering engineering plastics to support autonomous driving and increase driving comfort. In order to allow automotive manufacturers to achieve the optimum combination of lightweight construction, and vibration damping, BASF is providing noise, vibration, harshness solutions.

Engineering Plastics Market Research Scope:

The base year of the study is 2017, with forecast done up to 2023. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the engineering plastics market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of plastics in the engineering plastics market, and their specific applications in different types of industries.

Engineering Plastics Market Report: Industry Coverage

Types of Engineering Plastic: ABS, PA, PC, POM, PMMA, PEEK, PET, PBT, Cast Nylon

Types of End-User: Aerospace, Building & Construction, Food, Mechanical, Medical, Others

Types of Applications: CD/DVD, Medical implants, advanced batteries, Shoes, others

The Engineering Plastics Market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

- North America: The U.S., Canada, Mexico

- South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

- Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

- APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

- Middle East and Africa: Israel, South Africa, Saudi Arabia

"We also publish more than 100 reports every month in “Chemicals and Materials”, Go through the Domain if there are any other areas for which you would like to get a market research study."

Comments (0)

Post a Comment